- High-speed industrial CMOS sensor for superior 3D performance

- 3D profiles at up to 10 kHz in reduced ROI, 340 Hz full format

- GigE Vision and GenICam compatible for ease of use and simplified integration into systems and machine

- Accurate 3D, reflected light measurements

- Modular industrial design, IP68

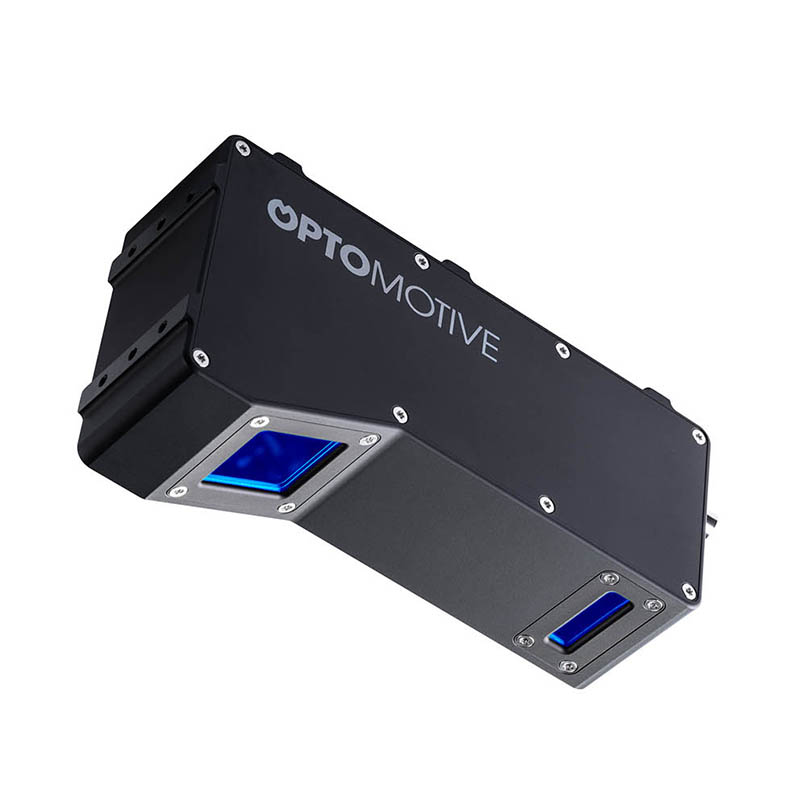

LOM sensor series consists of highly customizable and user-programmable high-speed laser triangulation sensors based on Optomotive’s FPGA camera technology. The series is designed for high performance inspection and can achieve inspection rates up to 10kHz. Excellent data of shiny and other challenging surfaces is generated by optimized optical design, in-camera PEAK Detection and blue laser light.

The sensors include high-performance ARM system-on-chip (SoC) technology, combined with turbocharged industrial AMS imaging sensor and top-quality laser line projector. The software on camera can also convert 3D points into mm in real time. Sensor series is factory calibrated and supports two simultaneous streams: image and 3D profile. It can also detect multiple profiles. For OEM and system integrator customers LOM series includes full customizable and user programmable open reference design for high-speed FPGA based camera and application development system. Its emphasis is on an open hardware-software development model, high-frame rates, real-time image processing on FPGA and modern graphical user interface support.

The reference design can be easily edited with standard Xilinx Vivado tools. Optomotive´s custom IP cores seamlessly integrate inside the Xilinx Vivado toolchain. Large portion of FPGA (PL) is free for a programming and development of additional algorithms, or implementation of additional IP cores. The 700MHz Dual Core ARM Cortex A9 Programmable Subsystem runs Linux OS with custom made EVO control and streaming stack. User applications or custom data post-processing can be easily added to existing design.

The high-quality sensor is capable of capturing min. 333 frames per second with a resolution of 2048x1088 pixels, up to 7435 frames per second with a resolution of 2048x32 pixels. Scanning can take place via a conveyor belt or on the spot so that the objects are exchanged. It uses high-precision hardware to provide you with the most accurate scans. The device is connected via gigabit ethernet for data transfer, through which it is also powered, which means that it does not need an additional power supply connection.

Targeted for

- Industrial quality control: to inspect defects, cracks or surface blemishes, size, position, dimension, foreign objects, quality.

- Robot guidance: when mounted on a robot arm it can provide feedback to the robot for positioning purposes

- General R&D

LOM SERIES

| Model | LOM025 | LOM100 | LOM125 | LOM220 | |

|---|---|---|---|---|---|

| Data points / Profile | 2048 | 2048 | 2048 | 2048 | |

| Triangulation angle [°] | 30 | 21 | 25 | 19 | |

| RESOLUTION X [µm] | near | 11 | 28 | 50 | 80 |

| mid | 12 | 36 | 62 | 110 | |

| far | 14 | 50 | 80 | 160 | |

| RESOLUTION Z [µm] | near | 1,6 | 6 | 9 | 18 |

| mid | 1,9 | 9 | 14 | 32 | |

| far | 2,5 | 18 | 26 | 77 | |

| Field of View [mm] | X near | 22 | 57 | 102 | 163 |

| X mid | 25 | 73 | 126 | 219 | |

| X far | 28 | 102 | 164 | 332 | |

| Z | 21 | 107 | 162 | 400 | |

| Working distance | 56 | 98 | 173 | 310 | |

| Measurement Range (mm) | 21 | 107 | 162 | 400 | |

| Laser | Blue | Blue | Blue | Blue |